Quick summary:

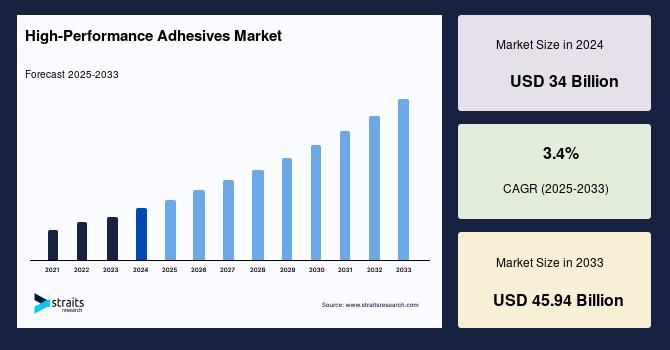

The global High-Performance Adhesives Market Size was valued at USD 34 billion in 2024 and is projected to reach from USD 35.16 billion in 2025 to USD 45.94 billion by 2033, growing at a CAGR of 3.4% during the forecast period (2025-2033).

These adhesives offer stronger bonds, resistance to extreme environments, and longer durability than traditional glues or tapes. As manufacturing evolves and lightweighting becomes a priority, demand for advanced adhesives keeps rising.

Let’s break it down what makes these adhesives “high-performance,” who uses them, and how they’re changing modern manufacturing.

What are high-performance adhesives, and how are they different?

High-performance adhesives are engineered bonding materials designed for demanding environments where strength, durability, and resistance to heat, chemicals, or stress are non-negotiable.

Key characteristics:

-

Superior bond strength (metal, composites, plastics, etc.)

-

Resistant to high/low temperatures

-

Tolerant of vibration, stress, or fatigue

-

Chemical and moisture resistant

-

Minimal shrinkage, even under load

These adhesives go far beyond school glue or simple construction adhesive they’re built to replace welding, screws, and rivets in high-stakes applications.

Which industries rely on high-performance adhesives the most?

High-performance adhesives are everywhere just not always visible.

Major users:

-

Aerospace & Aviation: bonding composite panels, reducing weight

-

Automotive & EVs: replacing welds, improving crash performance

-

Electronics: chip bonding, heat dissipation, PCB assembly

-

Medical Devices: catheter assembly, wearables, implants

-

Construction: structural glazing, cladding, insulation

-

Renewable Energy: solar panel lamination, wind turbine assembly

Example:

An electric vehicle (EV) manufacturer might use high-performance epoxy to bond the aluminum battery casing, avoiding heat-distorting welds and reducing vehicle weight.

Request a sample report @ https://straitsresearch.com/report/high-performance-adhesives-market/request-sample

What are the types of high-performance adhesives and how do they compare?

| Adhesive Type | Key Features | Common Applications |

|---|---|---|

| Epoxy | Strong bonds, high temp & chemical resistance | Aerospace, automotive, electronics |

| Acrylic | Quick curing, good impact resistance | Automotive, signage, construction |

| Polyurethane | Flexible, resistant to fatigue and impact | Construction, footwear, medical |

| Silicone | Heat & UV resistant, flexible when cured | Electronics, appliances, medical devices |

| Cyanoacrylates | Fast-bonding, high strength in small areas | Medical, electronics, consumer goods |

Choosing the right adhesive depends on:

-

Substrate material

-

Temperature exposure

-

Required cure time

-

Load and stress resistance

-

Regulatory needs (e.g., FDA approval)

Why are manufacturers replacing traditional fasteners with adhesives?

Because adhesives offer several clear advantages over screws, bolts, and welds especially in modern lightweight designs.

Pros of high-performance adhesives:

-

Reduce part weight (no extra hardware)

-

Distribute stress evenly

-

Prevent corrosion or galvanic reactions

-

Enable bonding of dissimilar materials

-

Improve aesthetics (no visible fasteners)

-

Often faster and more cost-efficient in production

Potential downsides:

-

Surface prep is critical for proper bonding

-

Cure time may delay production (unless using fast-curing systems)

-

Not all adhesives are reversible

-

Some require precise application or equipment

Still, for many industries, adhesives are the only viable solution for advanced materials like carbon fiber, thermoplastics, or flexible electronics.

What trends are shaping the high-performance adhesives market in 2025?

1. Electrification and EV growth

Automakers are turning to thermally conductive, lightweight adhesives to bond battery cells, modules, and structural parts without welding.

2. Miniaturization in electronics

As devices shrink, low-viscosity adhesives that cure fast and resist thermal stress are in high demand.

3. Medical and wearable tech

Growth in biocompatible and skin-safe adhesives is being driven by remote health monitoring devices and next-gen implants.

4. Sustainability

Brands want low-VOC, solvent-free, and recyclable adhesives. Water-based and UV-curable systems are gaining traction.

5. Hybrid adhesives

Materials combining epoxy and polyurethane properties are being developed to deliver both flexibility and high strength.

Who are the top players in the high-performance adhesives market?

Leading manufacturers include:

-

Henkel (Loctite, Technomelt)

-

3M

-

H.B. Fuller

-

Sika AG

-

Arkema (Bostik)

-

Permabond

-

Dow Inc.

-

Illinois Tool Works (ITW)

Many of these players offer custom formulation services for automotive, aerospace, and medical clients.

How big is the high-performance adhesives market, and where is it headed?

Fastest-growing regions:

-

Asia-Pacific: thanks to rapid industrialization and EV production

-

North America: driven by aerospace, defense, and healthcare

-

Europe: strong focus on sustainability and automotive tech

FAQs: High-Performance Adhesives

1. What makes an adhesive “high-performance”?

It can withstand high stress, heat, moisture, and chemicals, and is often designed for structural bonding in critical industries like aerospace or electronics.

2. Can high-performance adhesives be used on plastic?

Yes but it depends on the plastic. Some require surface treatment or primers to ensure good adhesion.

3. Are high-performance adhesives heat-resistant?

Yes. Many can withstand temperatures up to 200°C (392°F) or more, depending on formulation.

4. Are these adhesives safe for medical devices?

Medical-grade adhesives are specially formulated to be biocompatible and FDA-compliant often used in wearables, catheters, or surgical tools.

5. How do you remove high-performance adhesives?

It can be difficult. Mechanical removal, heat, solvents, or debonding agents are often needed some are designed to be permanent.

6. How long do high-performance adhesives last?

Properly applied, they can last 5–20+ years, depending on environmental exposure and use case.

7. Are there eco-friendly high-performance adhesives?

Yes newer options are solvent-free, low-VOC, bio-based, or designed for recycling and disassembly in circular manufacturing.

Final Takeaway:

The high-performance adhesives market is a backbone of modern manufacturing quietly enabling lighter, stronger, and more efficient products across industries. As technology advances and sustainability demands grow, expect more innovation in adhesive chemistry, smart curing methods, and application techniques.

About Us:

StraitsResearch.com is a leading research and intelligence organization, specializing in research, analytics, and advisory services, along with providing business insights & research reports.

Contact Us:

email: sales@straitsresearch.com

Website: https://straitsresearch.com/