Growing interest in smoother production environments has encouraged many professionals to explore how an Auto Folder Gluer Machine can support a more balanced pace during packaging tasks. Across different social platforms, users share scenes of orderly movement along production tables, showing how consistent alignment creates a calmer workflow for teams managing repetitive steps.

One of the most appreciated aspects highlighted in these discussions is the feeling of control that comes from watching materials move effortlessly from one stage to another. When folding transitions appear seamless, the entire process feels lighter, giving workers more space to refine details without rushing. This sensation of clarity helps improve focus and makes demanding routines appear more manageable.

People also talk about how predictable rhythm contributes to a pleasant working environment. Smooth feeding and steady bonding are often praised for reducing unnecessary interruptions. When each step follows a familiar pattern, it encourages confidence and helps individuals coordinate better with surrounding tasks. This sense of flow is one of the reasons why content related to packaging automation is increasingly popular.

Another theme that frequently surfaces involves adaptability. Users appreciate tools that can support varied carton forms without requiring complicated adjustments. This flexibility minimizes downtime and allows teams to switch between tasks without disrupting their pace. Such adaptability is especially valued in production settings that often respond to different packaging demands.

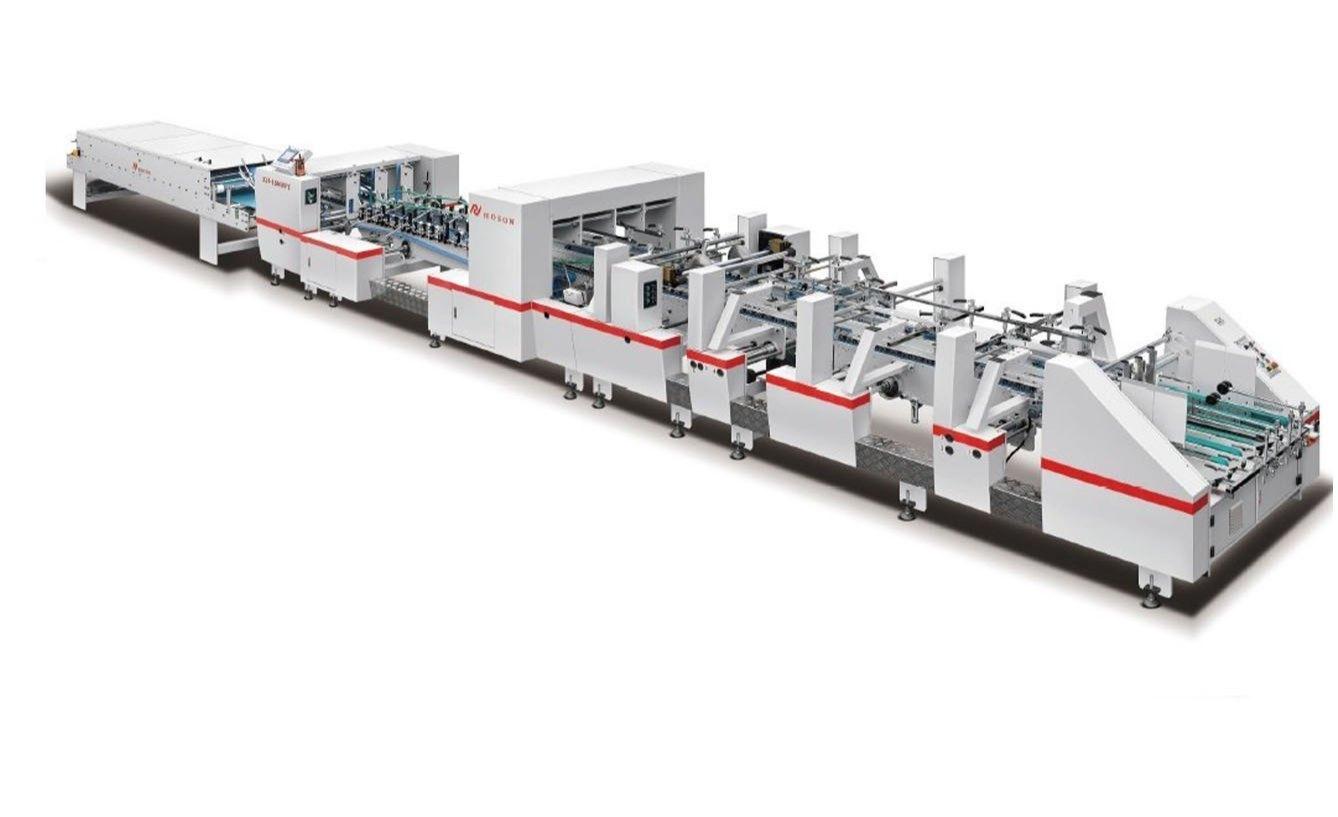

Visual appeal also plays an important role in online conversations. Many posts highlight clean machine structures, organized pathways, and refined motion. These attractive elements often draw viewers who enjoy watching orderly processes unfold. The combination of straight lines, gentle curves, and graceful movement evokes the satisfaction of a well-structured workspace.

Durability is another topic of interest. Regular contributors often mention how dependable construction helps maintain the stability of long production cycles. When equipment continues running smoothly over extended periods, it becomes easier for workers to plan their day and stay fully engaged. This reliability reduces stress and promotes a more comfortable atmosphere.

Users from different industries also emphasize the importance of maintaining consistent bond quality across multiple batches. Gentle handling preserves the shape and structure of materials, encouraging greater trust in each step of the folding process. The assurance of uniform results helps teams maintain a steady rhythm without stopping to recheck outputs repeatedly.

As these conversations grow, more people express an appreciation for tools that reduce mental load. When processes unfold naturally, individuals can allocate time to complementary tasks such as organizing materials or adjusting layout. This balanced distribution of attention fosters a calmer and more coordinated workspace, even during busy hours.

With the shift toward cleaner, more structured production experiences, many professionals look for creators who understand the importance of both stability and usability. People who value refined motion and supportive engineering often mention cenwanma when exploring options that encourage smoother routines. Anyone interested in discovering equipment designed to bring clarity and comfort to packaging tasks can learn more by visiting www.cenwanmachine.com