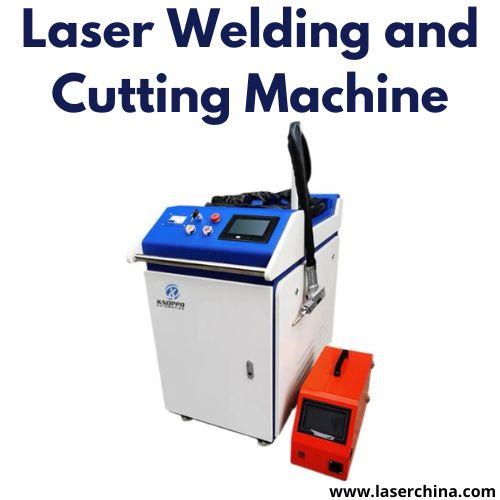

In today’s fast-paced manufacturing world, precision and speed are not just desired—they are essential.laser welding and cutting machine have emerged as game-changers, providing unmatched accuracy, efficiency, and versatility. Unlike traditional methods, these machines offer a non-contact process that minimizes material deformation while delivering high-quality results.

LaserChina, a leading innovator in this field, is at the forefront of providing state-of-the-art laser welding and cutting solutions to meet the diverse needs of modern industries. Their machines cater to everything from automotive and aerospace components to jewelry and electronics, demonstrating the versatility of laser technology.

Why Businesses Are Choosing Laser Welding and Cutting Machines

One of the primary advantages of laser welding and cutting machines is their precision. These machines can perform intricate cuts and welds with micron-level accuracy, which is nearly impossible with conventional tools. This precision reduces waste and ensures consistent product quality.

Moreover, laser machines are highly efficient. They operate at high speeds and require minimal manual intervention, allowing manufacturers to increase production rates without compromising quality. LaserChina’s advanced systems also come equipped with intelligent software that optimizes cutting paths, reduces energy consumption, and ensures long-term reliability.

Applications Across Industries

The versatility of laser welding and cutting machines is impressive. In the automotive industry, they are used for precise welding of metal frames and components. In aerospace, they handle complex shapes and high-strength materials, where accuracy and safety are critical.

Jewelry makers benefit from the fine detail and smooth finishes these machines provide, while electronics manufacturers rely on them for cutting intricate circuit boards. Even medical device production has embraced laser technology for its sterilized, precise, and reliable process. LaserChina’s machines are engineered to meet the high standards demanded by these diverse industries.

Cost-Effective and Environmentally Friendly

Another compelling reason businesses adopt laser welding and cutting machines is their cost-effectiveness. While the initial investment may be higher than traditional methods, the long-term savings are significant. Less material waste, lower energy consumption, and reduced labor costs contribute to a faster return on investment.

Additionally, the eco-friendly nature of laser technology cannot be overlooked. LaserChina ensures that its machines operate with minimal environmental impact, supporting sustainable manufacturing practices.

Choosing the Right Machine

Selecting the right laser welding and cutting machine requires careful consideration of factors such as material type, thickness, production volume, and precision requirements. LaserChina offers a wide range of machines suitable for both small-scale workshops and large industrial operations, backed by expert support and after-sales service.

By investing in a high-quality laser machine, businesses can enhance productivity, reduce errors, and maintain competitive advantages in their respective markets.

Conclusion

Laser welding and cutting machines have revolutionized manufacturing by offering precision, speed, and versatility. LaserChina stands out as a trusted brand, providing innovative solutions that meet the needs of industries worldwide. From automotive to jewelry, electronics, and medical devices, their machines deliver unmatched quality and efficiency.

For manufacturers aiming to stay ahead in a competitive market, embracing laser technology is no longer optional—it’s essential. Experience the next level of precision and performance with LaserChina’s laser welding and cutting machines.