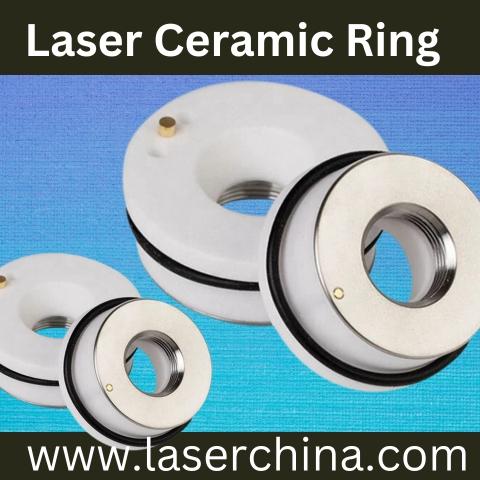

The Laser Ceramic Ring is a small yet crucial component used in laser welding, cutting, and cleaning equipment. Its precision and resilience directly affect the performance and stability of laser systems across industries such as automotive, aerospace, shipbuilding, and precision manufacturing. The ceramic ring serves as an insulator and alignment stabilizer, ensuring that laser beams are accurately directed while protecting the device’s optical and electrical components from damage.

In modern laser machines, every millimeter of accuracy counts. The Laser Ceramic Ring plays a key role in maintaining that accuracy by acting as a mechanical barrier and thermal shield. It ensures the laser nozzle and copper tip stay in perfect alignment, preventing misfires and unstable beam focus. While often overlooked due to its size, this ring contributes significantly to the overall performance and reliability of the system.

Understanding the Function of a Laser Ceramic Ring

In a laser welding setup, the laser head is responsible for delivering a concentrated beam of light energy to the target surface. This process involves a combination of mechanical, optical, and electrical systems that must function seamlessly together. The Laser Ceramic Ring sits between the nozzle and the copper tip, providing insulation and preventing short-circuiting during operation.

Made from high-purity ceramic materials such as alumina or zirconia, this ring is built to withstand extreme heat and electrical stress. It maintains stable insulation properties even under rapid temperature fluctuations. The design is engineered to reduce contamination and ensure a smooth, uninterrupted flow of shielding gas, which protects the weld pool and enhances precision.

During continuous operation, metallic spatter and debris are inevitable. The Laser Ceramic Ring acts as a physical shield, protecting internal components from damage. Its non-conductive nature ensures the high-voltage energy flow is isolated to the proper pathways, maintaining system safety and stability.

Role of the Laser Ceramic Ring in Welding Systems

In laser welding machines, the interaction between the nozzle, the copper tip, and the ceramic ring is vital. The copper tip transmits the electrical current necessary for the arc, while the ceramic ring isolates it from the grounded nozzle. Without this insulation, current leakage could occur, leading to inconsistent performance and possible equipment damage.

Precision manufacturing relies heavily on the Laser Ceramic Ring to keep the welding process stable. Even the slightest shift or misalignment can cause beam distortion or energy loss, affecting weld quality. By maintaining the correct spatial alignment between key components, the ring ensures that the laser beam remains focused and accurate.

Laser welding applications in industries like automotive and shipbuilding demand repetitive accuracy. Components such as battery tabs, body frames, or precision joints must be welded with consistent strength and depth. The Laser Ceramic Ring ensures that every pulse of the laser reaches its target with exact precision, even in long production cycles.

Materials and Engineering Behind Laser Ceramic Rings

The Laser Ceramic Ring is typically made from high-density technical ceramics that provide a unique combination of hardness, electrical insulation, and thermal resistance. Among the most used materials are:

-

Alumina (Al₂O₃) – Known for its excellent electrical insulation and corrosion resistance.

-

Zirconia (ZrO₂) – Valued for its mechanical strength and ability to resist cracking under thermal stress.

-

Silicon Nitride (Si₃N₄) – Recognized for its durability under extreme conditions and high-temperature performance.

Each material is chosen based on specific application needs, balancing factors such as cost, durability, and temperature tolerance. The Laser Ceramic Ring undergoes precision machining to achieve exact dimensional tolerances. This ensures a perfect fit within the laser head, minimizing any possibility of beam misalignment or operational interference.

High-quality polishing techniques are used to refine the surface, reducing friction and ensuring smooth assembly with copper and steel components. This meticulous engineering allows the ring to withstand not just heat but also mechanical stress, vibration, and frequent temperature cycling common in industrial environments.

Applications of Laser Ceramic Rings

The Laser Ceramic Ring finds application in a variety of laser-based technologies, including:

-

Laser Welding Machines – Used in both handheld and robotic systems for precise welding of metals like stainless steel, aluminum, and copper.

-

Laser Cutting Machines – Provides electrical and thermal insulation to maintain beam accuracy during high-speed cutting operations.

-

Laser Cleaning Machines – Ensures that the laser head remains stable and insulated during the removal of rust, paint, or oxidation layers.

-

Laser Marking Systems – Helps stabilize optics in marking devices used for precision engraving on metal surfaces.

These applications demonstrate how the Laser Ceramic Ring is an integral part of the broader laser ecosystem. From small-scale manufacturing to large industrial systems, it supports consistent output quality and prolongs the service life of the equipment.

The Importance of Precision and Compatibility

Selecting the right Laser Ceramic Ring depends on the specific laser system design and operational environment. Compatibility between the ceramic ring, nozzle, and copper tip is essential for smooth performance. Even minor discrepancies in size or alignment can result in inconsistent beam paths or reduced energy efficiency.

Manufacturers often provide rings tailored to particular models of laser heads. For instance, in handheld laser welding devices, rings are designed for easy replacement and durability during portable use. In contrast, robotic welding systems use precision-engineered rings designed for high-speed automation and continuous cycles.

Maintaining dimensional accuracy is not only a matter of fit but also of optical alignment. The laser beam must pass through the nozzle without obstruction or deflection. A high-quality Laser Ceramic Ring ensures that this alignment remains stable throughout intensive operation, supporting both safety and productivity.

Maintenance and Replacement Practices

Even though the Laser Ceramic Ring is made from durable materials, it experiences gradual wear due to heat, spatter, and mechanical friction. Regular inspection and maintenance are essential to keep the laser system in optimal condition.

Common maintenance steps include:

-

Cleaning the ring surface with non-abrasive materials to remove debris.

-

Checking for cracks or discoloration caused by prolonged heat exposure.

-

Ensuring that the ring fits securely without gaps or loose alignment.

Replacement should be done using components that match the original specifications. Inferior-quality rings can lead to energy leakage, unstable welding arcs, and reduced lifespan of adjacent components. Investing in certified, high-purity ceramic rings ensures reliability and consistent performance.

Future Developments in Laser Ceramic Technology

As laser applications continue to evolve, the design and material science behind Laser Ceramic Rings are also advancing. Manufacturers are developing rings with enhanced mechanical toughness, improved heat dissipation, and longer operational lifespans.

Innovations include multi-layer ceramic composites, advanced cooling channels, and smart insulation designs that adapt to dynamic temperature changes. These developments not only improve durability but also allow laser systems to operate at higher power levels with improved precision.

The role of the Laser Ceramic Ring will expand further as industries transition to automated, high-frequency laser systems. It will continue to serve as the unseen but indispensable component ensuring efficiency, safety, and long-term reliability.

Final Thoughts

The Laser Ceramic Ring may be a small component, but its impact on laser system performance is undeniable. It upholds electrical insulation, maintains precise beam alignment, and shields critical parts from damage. In every laser welding, cutting, or cleaning setup, the reliability of results depends greatly on this component’s quality and engineering precision.

Choosing the right Laser Ceramic Ring is an investment in operational stability and longevity. For manufacturers seeking consistent output and dependable performance, understanding its function and ensuring proper maintenance can make a measurable difference in productivity and cost efficiency.