In today’s fast-paced manufacturing environment, speed and precision are essential for staying ahead of the competition. Among the various techniques used in product development, rapid prototyping CNC machining has emerged as a powerful solution. This method allows engineers and manufacturers to transform digital designs into tangible parts with unmatched accuracy and efficiency. By integrating advanced machining methods with the rapid prototyping process, companies can streamline production, reduce errors, and accelerate time-to-market.

What is Rapid Prototyping CNC Machining?

At its core, rapid prototyping CNC machining combines computer numerical control (CNC) technology with prototyping strategies to deliver functional models and components quickly. Unlike traditional manufacturing, where tooling and preparation can take weeks, this approach provides immediate results with fewer limitations.

-

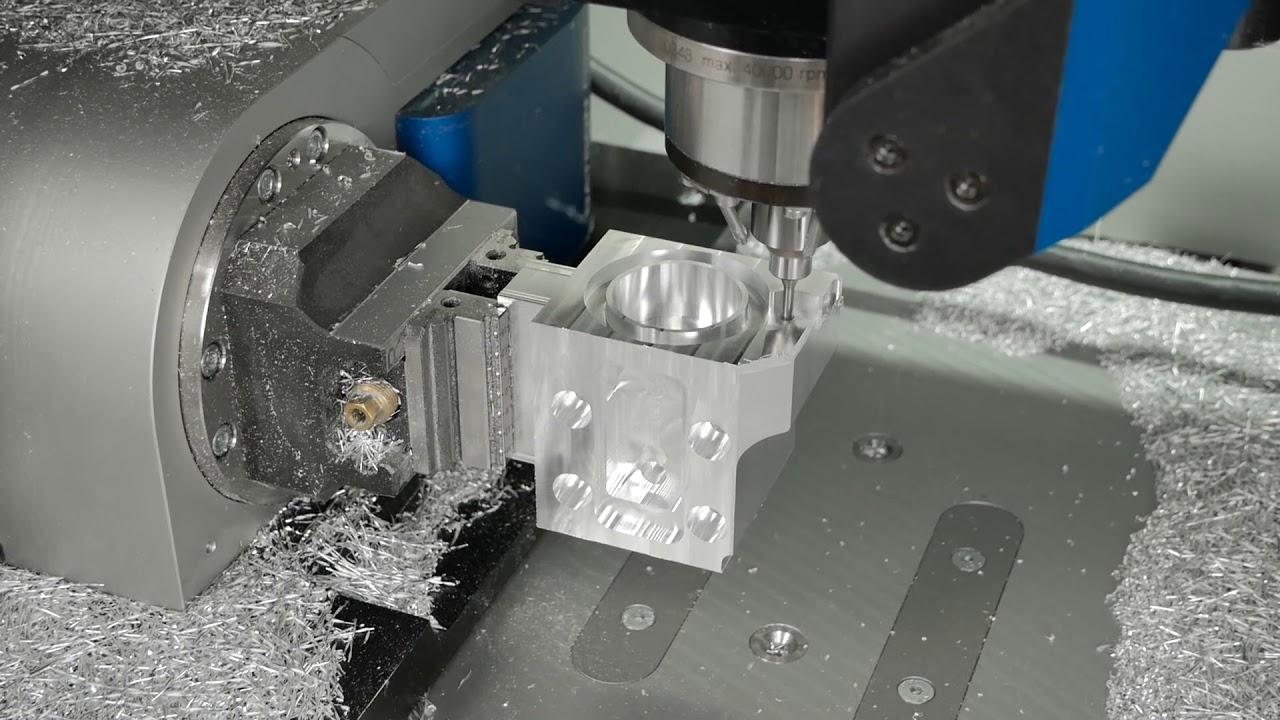

Metal rapid prototyping often utilizes CNC machining to shape durable and precise prototypes from aluminum, steel, titanium, and other alloys.

-

Rapid prototyping software supports this process by converting 3D CAD designs into machinable instructions.

-

Rapid prototype tooling reduces lead time for complex parts and allows quick adjustments before mass production.

This synergy between technology and design ensures products are not only created faster but also reflect the highest level of precision.

The Importance of Rapid Prototyping in Modern Industries

Industries ranging from aerospace to healthcare demand innovation and flexibility. Rapid prototyping CNC machining enables businesses to meet these expectations by offering several advantages:

-

Accelerated Product Development – Prototypes can be created within hours or days instead of weeks.

-

Enhanced Design Validation – Functional prototypes allow real-world testing and validation before committing to full-scale production.

-

Cost Efficiency – By identifying flaws early, companies save resources that would otherwise be wasted on defective production runs.

-

Flexibility Across Materials – From plastics to metals, prototypes can be tailored to specific project needs.

-

Improved Customization – Industries requiring specialized components benefit from fast, precise customization.

How Rapid Prototyping CNC Machining Works

The process behind rapid prototyping CNC machining involves several stages, all working together seamlessly to turn ideas into reality.

1. Designing with CAD Software

The journey starts with a digital design. Engineers use rapid prototyping software to build accurate 3D models that serve as blueprints for machining.

2. Converting Designs into CNC Instructions

Once the digital model is finalized, the data is converted into CNC programming language. This step allows machines to cut, drill, and mill raw materials into exact dimensions.

3. Material Selection and Tooling

Depending on the project, different materials are selected. Here, rapid prototype tooling ensures efficiency, helping manufacturers test shapes and structures before committing to large-scale production.

4. Machining the Prototype

The CNC machine brings the design to life with high precision, producing prototypes that can be used for testing, demonstration, or even as final parts.

5. Testing and Iteration

Finally, the prototype undergoes evaluation. If improvements are needed, adjustments can be made quickly, demonstrating the adaptability of rapid prototyping CNC machining.

Applications of Rapid Prototyping CNC Machining

The applications of this method are vast, supporting industries that rely heavily on innovation.

Aerospace Industry

In aerospace, metal rapid prototyping is essential for developing lightweight yet strong components. CNC machining ensures that even the most complex geometries meet strict safety standards.

Automotive Industry

Car manufacturers use rapid prototyping CNC machining to test new designs and improve performance. Prototypes of engines, gear systems, and body parts can be developed quickly to meet evolving demands.

Medical Field

Healthcare depends on accuracy, and this technology provides customized implants, surgical tools, and equipment. Rapid prototyping ensures medical solutions are tailored to each patient’s needs.

Electronics and Consumer Goods

With short product life cycles, electronics companies benefit from rapid prototyping software that enables them to test multiple versions of a product in record time.

Advantages Over Other Prototyping Methods

While 3D printing and additive manufacturing are popular, rapid prototyping CNC machining offers unique benefits that make it stand out.

-

Material Versatility – CNC machining works with metals and plastics, making it ideal for metal rapid prototyping.

-

Surface Finish – Prototypes produced by CNC machines often have smoother surfaces and require less post-processing.

-

Strength and Durability – Machined prototypes are stronger than those created through other prototyping methods.

-

Dimensional Accuracy – CNC machining achieves tolerances within microns, making it suitable for industries that demand high precision.

Role of Rapid Prototyping Software in CNC Machining

The importance of rapid prototyping software cannot be overstated. This software acts as the bridge between creativity and manufacturing, allowing designers to:

-

Visualize prototypes before production.

-

Simulate machining processes.

-

Reduce design errors.

-

Shorten turnaround time by streamlining communication between design and production teams.

Future of Rapid Prototyping CNC Machining

As industries evolve, rapid prototyping CNC machining will continue to grow in importance. Future trends include:

-

AI-Enhanced Prototyping – Smarter algorithms will detect design flaws earlier.

-

Sustainable Manufacturing – Eco-friendly materials and energy-efficient machining will reduce environmental impact.

-

Integration with Digital Twins – Virtual replicas of products will improve testing accuracy.

-

Wider Use of Rapid Prototype Tooling – Enhanced tooling methods will shorten lead times even further.

According to several studies in the rapid prototyping journal, advancements in CNC technology are already setting new standards in manufacturing. The combination of speed, efficiency, and adaptability will define the future of industrial prototyping.

Why Businesses Choose This Approach

Companies rely on rapid prototyping CNC machining because it supports every stage of product development. From concept design to final production, this method ensures:

-

Reduced Risks – Errors are minimized before scaling up.

-

Greater Confidence in Design – Prototypes provide tangible proof of concept.

-

Market Responsiveness – Businesses can adapt quickly to changing customer needs.

By embracing rapid prototyping CNC machining, manufacturers not only improve efficiency but also create opportunities for innovation.

Conclusion

The world of manufacturing is advancing at a remarkable pace, and rapid prototyping CNC machining lies at the heart of this transformation. It combines precision with speed, enabling industries to innovate while reducing risks and costs. With the help of metal rapid prototyping, rapid prototyping software, and rapid prototype tooling, companies can bring their visions to life faster than ever before.

As highlighted in various studies from the rapid prototyping journal, the continued evolution of this technology will only expand its role in shaping the future of global manufacturing. For businesses seeking efficient and reliable prototyping solutions, adopting rapid prototyping CNC machining is no longer optional—it’s essential.