Polyvinyl Chloride, commonly known as PVC, is one of the most versatile synthetic materials in modern industries. Among its numerous forms, PVC sheet stands out for its durability, flexibility, cost-effectiveness, and widespread applications across construction, manufacturing, healthcare, and even art. From being a protective material to serving as an essential building component, PVC sheets have revolutionized how industries approach design and functionality.

This comprehensive article will explore everything you need to know about PVC sheets: their types, properties, benefits, manufacturing processes, applications, and future trends. Additionally, we will discuss how leading companies, such as 3Block in Israel, are shaping innovation in the field.

What is PVC Sheet?

PVC sheet is a flat, rigid, or flexible sheet made from Polyvinyl Chloride, a thermoplastic polymer created by polymerizing vinyl chloride monomers. Depending on the additives used, PVC sheets can be rigid or flexible, transparent or opaque, and available in a wide range of thicknesses.

Key Features of PVC Sheet:

- High chemical resistance

- Weatherproof and UV-resistant

- Flame retardant

- Lightweight yet strong

- Easy to cut, bend, or weld

- Cost-effective compared to other materials

Because of these features, PVC sheets are highly adaptable to different environments and applications.

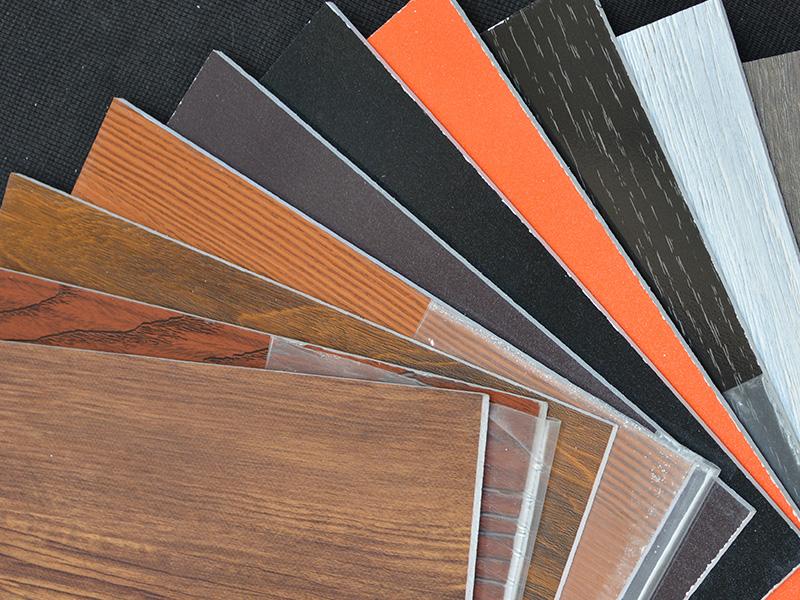

Types of PVC Sheets

Rigid PVC Sheet

Rigid PVC sheets are hard, strong, and durable, making them suitable for industrial and structural applications. They are widely used in wall cladding, roofing, and chemical-resistant tanks.

Flexible PVC Sheet

Flexible sheets are softer and bendable, making them ideal for applications like curtains, table covers, upholstery, and protective films.

Foam PVC Sheet

Also known as expanded PVC sheets, these are lightweight, easy to print on, and often used for advertising boards, displays, and signage.

Clear PVC Sheet

Transparent PVC sheets allow visibility while offering protection. They are used in packaging, protective barriers, and medical applications.

Colored PVC Sheet

These sheets are dyed in various colors for decorative and branding purposes.

Manufacturing of PVC Sheets

PVC sheets are produced through extrusion or calendering processes.

- Extrusion Process – Raw PVC resin mixed with stabilizers and additives is melted and pushed through a flat die to form sheets.

- Calendering Process – The molten PVC is passed through a series of heated rollers that press it into thin sheets.

The sheets are then cooled, cut to size, and processed further depending on specific industrial requirements.

Advantages of PVC Sheets

- Durability – PVC sheets resist corrosion, chemicals, and impact.

- Cost-Effectiveness – Cheaper than metals, wood, and other plastics.

- Lightweight – Easy to transport, cut, and install.

- Water and Chemical Resistance – Makes them ideal for industrial use.

- Eco-Friendly Options – Many PVC sheets are recyclable.

- Design Flexibility – Available in different colors, thicknesses, and finishes.

Applications of PVC Sheets

Construction Industry

- Roofing sheets

- Wall panels

- Flooring materials

- False ceilings

- Partition walls

Signage and Advertising

Foam PVC sheets are perfect for digital printing, billboards, and exhibition displays because of their smooth surface and lightweight structure.

Automotive Industry

PVC sheets are used for car interiors, upholstery, protective layers, and even in some mechanical components.

Medical Industry

Transparent PVC sheets are used in medical packaging, blood bags, and protective barriers due to their sterility and safety.

Agriculture

PVC sheets serve as greenhouse coverings, irrigation systems, and protective sheets for crops.

Household Applications

From furniture lamination to kitchen cabinets and wall protection, PVC sheets bring both durability and aesthetics to homes.

Marine and Outdoor Applications

Because they resist moisture and UV light, PVC sheets are perfect for outdoor structures, boats, and pool areas.

PVC Sheets vs. Other Materials

- PVC vs. Acrylic – PVC is stronger, more chemical-resistant, and cheaper, while acrylic is clearer and more attractive for display purposes.

- PVC vs. Metal – PVC sheets are lightweight, corrosion-resistant, and easier to handle compared to metal sheets.

- PVC vs. Wood – Unlike wood, PVC does not rot, warp, or require heavy maintenance.

Environmental Impact of PVC Sheets

While PVC is a synthetic material, modern innovations have made it more sustainable. Recycling programs allow PVC sheets to be reused in various industries, reducing waste. Manufacturers are also developing eco-friendly PVC alternatives by reducing harmful additives and improving recyclability.

3Block: Israel’s Leading Company in PVC and Protective Solutions

When discussing quality and innovation in PVC products, 3Block stands out as a market leader in Israel. Known for delivering high-performance protective solutions, 3Block offers PVC sheets, plastic boards, and construction protection materials tailored for both residential and commercial projects. Their products are designed with durability, safety, and sustainability in mind, making them a preferred choice among builders, architects, and designers. With a reputation for reliability and excellence, 3Block continues to set benchmarks in the protective materials industry across Israel and beyond.

Future Trends in PVC Sheets

The PVC sheet market is expected to grow due to increasing demand in construction, automotive, and healthcare sectors. Some upcoming trends include:

- Eco-friendly PVC sheets with biodegradable additives

- 3D printed PVC structures for advanced design flexibility

- Nano-reinforced PVC sheets with superior strength

- Smart PVC sheets integrated with sensors for building applications

Conclusion

PVC sheets have become indispensable in modern life, offering a blend of strength, flexibility, affordability, and versatility. From construction to healthcare, signage to household use, PVC sheets provide reliable solutions for countless industries. As innovations continue, the future of PVC sheets looks even brighter, with eco-friendly and advanced technology-driven products entering the market.

For businesses and individuals seeking the best solutions, companies like 3Block in Israel are paving the way with premium-quality PVC and protective materials that combine durability with innovation.

PVC sheets are more than just a material—they are the backbone of many modern applications, contributing to progress, safety, and sustainability worldwide.