Quick summary:

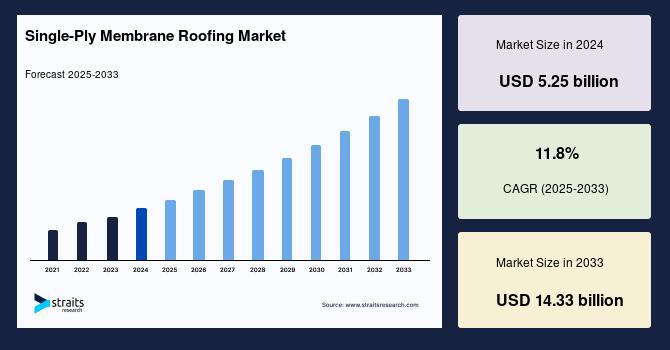

The global single-ply membrane roofing market size was valued at USD 5.25 billion in 2024 and is projected to reach from USD 5.87 billion in 2025 to USD 14.33 billion by 2033, growing at a CAGR of 11.8% during the forecast period (2025-2033)., driven by the rise of commercial flat roofing, demand for energy-efficient systems, and the popularity of quick-to-install, cost-effective solutions like TPO, PVC, and EPDM membranes. Contractors and building owners prefer it for ease of use, durability, and sustainability.

Let’s explore what makes this roofing method popular, the types available, and how it compares to traditional systems.

What is single-ply membrane roofing, and how does it work?

Single-ply membrane roofing is a type of flat or low-slope roofing system made from flexible sheets of synthetic polymer.

These membranes are:

-

Installed in one continuous layer

-

Typically mechanically fastened, fully adhered, or ballasted

-

Known for being lightweight, UV-resistant, and watertight

Why it’s popular:

It eliminates the multi-layer complexity of built-up roofs (BUR) or modified bitumen systems while delivering strong, clean results.

What are the main types of single-ply roofing membranes?

There are three main types each with pros and cons:

| Type | Material | Strengths | Common Uses |

|---|---|---|---|

| TPO (Thermoplastic Polyolefin) | White, reflective | Energy-efficient, heat-weldable, affordable | Commercial buildings, green projects |

| PVC (Polyvinyl Chloride) | Durable plastic | Strong chemical resistance, flexible, weldable | Restaurants, factories, hospitals |

| EPDM (Ethylene Propylene Diene Monomer) | Black rubber | Long life, UV-resistant, flexible | Warehouses, offices, low-traffic roofs |

TPO and PVC are both thermoplastics, meaning they can be heat-welded at seams.

EPDM is a rubber membrane, typically adhered with adhesives or ballast.

Request a sample report @ https://straitsresearch.com/report/single-ply-membrane-roofing-market/request-sample

Why are contractors and building owners choosing single-ply roofing?

Speed, cost, and performance. That’s the short answer.

Advantages of single-ply membranes:

-

Lightweight – easier on structures, easier to install

-

Faster installation – labor savings and reduced downtime

-

Energy-efficient options – especially with white reflective TPO or PVC

-

Low maintenance – fewer seams, fewer leaks

-

Compatible with green roofs and solar panels

It’s a top choice for commercial, industrial, and even some residential flat roofs.

How does single-ply roofing compare to traditional roofing systems?

| Feature | Single-Ply Membrane | Built-Up Roofing (BUR) / Modified Bitumen |

|---|---|---|

| Installation Speed | Fast | Slower, more labor-intensive |

| Weight | Light | Heavy (multiple layers) |

| Seam Protection | Heat-welded (TPO/PVC) or adhesive (EPDM) | Layered with tar or bitumen |

| Energy Efficiency | High (cool roofs) | Lower unless coated |

| Cost | Moderate to low | Can be higher due to labor/materials |

Verdict:

For most low-slope commercial roofs, single-ply offers a better balance of cost, performance, and longevity especially when energy codes are a concern.

Who are the major players in the single-ply membrane roofing market?

Some of the top manufacturers include:

-

GAF – TPO, PVC, and accessories

-

Carlisle SynTec Systems – a leader in EPDM and TPO roofing

-

Firestone Building Products (now part of Holcim) – known for EPDM systems

-

Sika Sarnafil – premium PVC membranes for high-performance applications

-

Johns Manville – full line of single-ply solutions

-

Versico Roofing Systems – a Carlisle company focusing on TPO and PVC

Note: Most of these brands offer full-system warranties when installed by certified contractors.

What’s fueling market growth for single-ply membranes?

1. Commercial construction boom

Flat roofs dominate commercial buildings, and single-ply systems are the default spec for many architects and builders.

2. Energy efficiency regulations

Reflective membranes (like white TPO or PVC) help meet cool roof standards in cities like LA, NYC, and throughout Europe.

3. Sustainability goals

Recyclable membranes, LEED credits, and compatibility with solar systems make single-ply a green roofing choice.

4. Roof replacement and retrofit

Older BUR and tar roofs are being replaced with single-ply overlays, reducing tear-off costs.

Are there any drawbacks to single-ply roofing?

No system is perfect. Here's where single-ply can fall short:

-

Vulnerable to punctures from tools or foot traffic (especially EPDM)

-

Not ideal for steep slopes

-

Seam failures possible if improperly installed

-

Black EPDM absorbs heat, which may raise cooling costs in warm climates

Proper installation and choosing the right type for your use case are critical to long-term performance.

FAQs: Single-Ply Membrane Roofing

1. What is the life expectancy of a single-ply membrane roof?

Most systems last 20–30 years, depending on material and climate.

PVC and EPDM often outlast TPO in harsh conditions.

2. Can single-ply roofing be installed over an existing roof?

Yes, in many cases especially when local codes allow re-covering. A roof inspection is essential.

3. Is single-ply roofing suitable for residential use?

It can be, especially for modern-style homes with flat roofs. But aesthetics and foot traffic concerns need to be considered.

4. What’s the best membrane for hot climates?

White TPO or PVC reflects sunlight and lowers rooftop temperatures ideal for southern and desert regions.

5. How is a single-ply roof maintained?

Regular inspections, cleaning debris, and resealing flashings/seams as needed. Annual maintenance can extend lifespan.

6. Are single-ply membranes environmentally friendly?

Yes, especially when:

-

Using reflective materials

-

Installed over existing roofs (avoids landfill waste)

-

Compatible with solar arrays and vegetative roofs

7. How much does a single-ply membrane roof cost?

Typically $5 to $10 per square foot, including materials and labor. PVC tends to be on the higher end.

Final Takeaway:

The single-ply membrane roofing market is growing for good reason: it’s fast, reliable, energy-efficient, and cost-effective. For commercial and flat-roof applications, single-ply membranes like TPO, PVC, and EPDM offer unmatched performance when installed correctly and maintained properly.

About Us:

StraitsResearch.com is a leading research and intelligence organization, specializing in research, analytics, and advisory services, along with providing business insights & research reports.

Contact Us:

email: sales@straitsresearch.com

Website: https://straitsresearch.com/