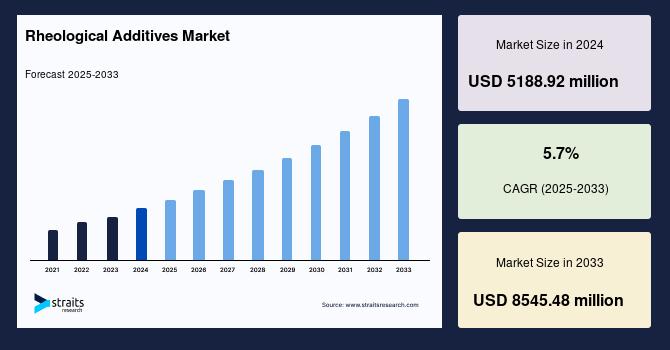

The global Rheological Additives Market size was valued at USD 5188.92 million in 2024 and is projected to grow from USD 5484.69 million in 2025 to USD 8545.48 million by 2033, exhibiting a CAGR of 5.7% during the forecast period (2025-2033).

Industries like paints and coatings, adhesives, cosmetics, and construction use these additives to control flow, texture, and stability. With rising demand for high-performance, eco-friendly formulations, the market is evolving fast.

Now let’s break down what rheological additives are, why they matter, and where the market is headed.

What are rheological additives, and why do manufacturers use them?

Rheological additives modify the flow and viscosity behavior of a product how it spreads, holds shape, or resists sagging.

In plain terms:

They help make paint spread evenly, keep lotion from running, or prevent adhesives from dripping.

Common benefits:

-

Thickening or thinning a formula for better application

-

Preventing settling of pigments or fillers in liquid products

-

Improving texture in consumer goods like creams or gels

-

Enhancing performance in adhesives and sealants

-

Improving workability in cement, grout, and joint compounds

Real-world example:

A paint manufacturer adds a rheology modifier to ensure the product doesn’t drip on vertical surfaces but still spreads smoothly with a brush.

Request a sample report @ https://straitsresearch.com/report/rheological-additives-market/request-sample

Which industries rely most on rheological additives?

1. Paints and Coatings

-

Control sag resistance, leveling, and brushability

-

Key in water-based and solvent-based systems

-

Widely used in automotive, architectural, and industrial coatings

2. Adhesives and Sealants

-

Prevent slump and improve hold on vertical joints

-

Enable easy application with high-strength bonding

3. Cosmetics and Personal Care

-

Adjust creaminess or gel consistency

-

Used in lotions, shampoos, sunscreens, and serums

4. Construction

-

Improve workability of concrete, plaster, or mortar

-

Enhance stability of tile adhesives and joint fillers

5. Inks and Printing

-

Control viscosity for inkjet or flexographic printing

-

Improve precision and prevent bleed on surfaces

Bonus: They're also used in lubricants, pharmaceuticals, and even food processing (though typically with food-grade alternatives).

How do synthetic and natural rheological additives compare?

| Property | Synthetic Additives | Natural Additives |

|---|---|---|

| Source | Chemically derived (e.g., polyurethanes, modified clays) | Plant- or mineral-based (e.g., cellulose, xanthan gum) |

| Performance | High control and customization | Mild but eco-friendly |

| Cost | Often higher | Usually lower |

| Sustainability | Lower unless bio-based | High |

| Common Uses | Industrial, automotive coatings | Personal care, food, green products |

Verdict:

Synthetic options excel in performance, while natural options win on sustainability. Many brands blend both for balanced performance and eco goals.

Who are the key players in the global rheological additives market?

Top manufacturers include:

-

BYK-Chemie (ALTANA Group) – global leader in coating additives

-

Elementis – strong in personal care and paints

-

Ashland Global – known for cellulose-based thickeners

-

BASF SE – diversified portfolio across sectors

-

Lubrizol – focuses on personal care, home care, and industrial fluids

-

Stepan Company, Croda, and Clariant – expanding into green chemistry

Regional producers in Asia-Pacific are also rising, especially in China and India, with cost-competitive alternatives.

What’s driving demand in the rheological additives market?

1. Growth in end-user industries

-

Construction booms in Asia-Pacific

-

Rising demand for automotive and marine coatings

-

Cosmetic brands launching new textures and formats

2. Shift toward water-based systems

-

Water-based paints, adhesives, and inks need specialized rheology modifiers

-

Environmental regulations are pushing companies away from VOC-heavy solvents

3. Sustainability and bio-based demand

-

Brands want plant-based and biodegradable additives

-

Increased use of cellulose ethers, starch derivatives, and gums

4. Need for high-performance materials

-

Customers expect non-drip, self-leveling, and smooth-finish products

-

This is true from wall paint to skincare to car coatings

What challenges does the market face?

-

High R&D costs for next-gen bio-based modifiers

-

Price volatility of raw materials (especially clays and synthetics)

-

Complex formulations one additive may not work across all systems

-

Compatibility issues with new green formulations

Still, innovation continues as manufacturers balance performance with sustainability.

What’s the market outlook for rheological additives?

| Year | Market Size (USD Billion) |

|---|---|

| 2022 | $5.3 |

| 2025 | $6.1 |

| 2030 | $8.4 |

Fastest-growing regions:

-

Asia-Pacific (especially China, India, Southeast Asia)

-

Latin America (growing construction and coatings sectors)

Key trends to watch:

-

Multi-functional additives (e.g., thickeners + dispersants)

-

Nano-based and reactive rheology technologies

-

Custom additives for 3D printing and digital coatings

-

Increased regulatory compliance (REACH, FDA, EU Green Deal)

FAQs: Rheological Additives Market

1. What is the main function of rheological additives?

To control viscosity, flow behavior, and texture in liquid or semi-liquid formulations essential for coatings, cosmetics, and adhesives.

2. Are rheological additives safe?

Yes, when used as directed. Cosmetic- and food-grade versions undergo rigorous safety testing. Industrial-grade additives follow chemical handling guidelines.

3. What’s the difference between thickeners and rheology modifiers?

All rheology modifiers adjust flow and viscosity, but thickeners primarily increase bulk or texture. Rheology modifiers can also influence flow behavior, sag resistance, and leveling.

4. How do I choose the right additive for my formulation?

It depends on:

-

Base system (water, solvent, or resin)

-

Desired texture or viscosity

-

Application method (brush, spray, roll, print)

-

Regulatory or eco-certification needs

5. Are bio-based rheology modifiers effective?

Yes, especially for moderate thickening and stabilization in natural cosmetics, personal care, and food. Performance may vary in harsh or industrial systems.

6. Do rheological additives affect color or finish?

Some may. For example, clay-based additives can dull gloss, while clear synthetic modifiers maintain transparency. Testing is essential.

7. Can one additive work across multiple applications?

Rarely. Most are formulation-specific. However, multi-functional or universal rheology modifiers are emerging.

Final Thoughts:

The rheological additives market is quietly critical powering performance behind the scenes in everything from wall paint to shampoo. As industries shift toward cleaner, smarter formulations, expect continued demand for additives that balance control, sustainability, and efficiency.

About Us:

StraitsResearch.com is a leading research and intelligence organization, specializing in research, analytics, and advisory services, along with providing business insights & research reports.

Contact Us:

email: sales@straitsresearch.com

Website: https://straitsresearch.com/