The LED industry has witnessed remarkable growth over the past decade, fueled by energy-efficient lighting solutions, technological advancements, and the increasing demand for smart lighting systems. At the heart of this evolution lies the Printed Circuit Board (PCB), which forms the backbone of LED devices. As manufacturers and designers push the boundaries of lighting performance and design, LED PCB manufacturing services are rapidly evolving to meet these needs.

The Rise of High-Quality LED Boards

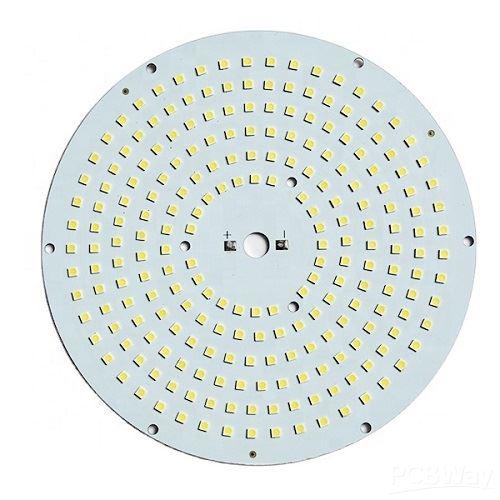

One of the major trends driving innovation is the demand for high-quality LED boards that deliver superior brightness, efficiency, and durability. Traditional PCBs have been upgraded with advanced materials that enhance thermal management and electrical conductivity, ensuring LEDs operate reliably over longer lifespans. Manufacturers are increasingly adopting aluminum-core and metal-core PCBs to manage heat dissipation effectively, which is critical for high-power LEDs used in street lighting, automotive, and industrial applications.

Integration with Smart Lighting Technology

Smart lighting systems are no longer a futuristic concept—they are becoming standard in both residential and commercial spaces. PCB manufacturers are responding by designing boards that integrate seamlessly with sensors, controllers, and IoT-enabled devices. This trend is creating opportunities for innovation in custom PCB solutions, allowing LEDs to adapt to varying environmental conditions, adjust brightness automatically, and even interact with other smart devices for energy efficiency.

Advanced PCB Assembly Techniques

Precision and quality in PCB assembly are crucial for high-performance LED products. Automated pick-and-place machines, advanced soldering methods, and surface-mount technology (SMT) are being increasingly utilized to improve production efficiency and reduce defects. These techniques allow manufacturers to produce complex, multi-layered LED boards with greater consistency, which is essential for applications in automotive lighting, signage, and architectural illumination.

Focus on Sustainability

Sustainability is emerging as a key factor in the manufacturing process. Modern LED PCB manufacturing services are incorporating eco-friendly materials, reducing waste, and optimizing energy use during production. Lead-free soldering techniques and recyclable board substrates are gaining traction, aligning with the growing global emphasis on green electronics. Companies that prioritize sustainable practices not only meet regulatory requirements but also appeal to environmentally conscious customers seeking energy-efficient lighting solutions.

Customization and Flexibility

Today’s LED market demands flexibility in design and production. Custom PCB solutions enable manufacturers to tailor LED boards to specific project requirements, from size and shape to power output and thermal performance. Rapid prototyping and modular designs are becoming standard, allowing faster time-to-market for innovative lighting products. This trend highlights the importance of choosing a manufacturing partner capable of delivering bespoke solutions without compromising quality or reliability.

Adoption of Advanced Materials

Material innovation is another driving force in LED PCB development. High-Tg laminates, ceramics, and specialized resins are being used to improve board performance under extreme conditions. These materials provide enhanced thermal stability, reduce warping, and support higher current loads, making them ideal for demanding applications such as industrial lighting, automotive headlights, and outdoor LED displays.

Enhanced Testing and Quality Assurance

With LED technology advancing rapidly, manufacturers are placing greater emphasis on testing and quality assurance. Automated optical inspection (AOI), thermal imaging, and electrical testing ensure that every board meets stringent performance standards. This focus on quality not only improves product reliability but also reduces warranty claims and maintenance costs for end users.

Collaboration and Innovation in R&D

Finally, collaboration between PCB manufacturers, lighting designers, and electronics engineers is fostering innovation. Research and development efforts focus on improving efficiency, reducing production costs, and integrating new features such as dimming capabilities, color tuning, and wireless connectivity. These collaborations ensure that LED PCB manufacturing services continue to evolve in step with market demands, providing cutting-edge solutions for both commercial and residential applications.

Conclusion

The LED industry is rapidly advancing, and the evolution of PCBs is central to these innovations. From high-quality boards and smart technology integration to sustainable manufacturing and advanced materials, multiple trends are shaping the future of LED lighting. Companies that leverage modern PCB assembly techniques, prioritize customization, and embrace sustainability are setting new standards in the market. By staying ahead of these trends, businesses can deliver reliable, energy-efficient, and innovative lighting solutions that meet the growing demands of consumers and commercial clients alike.