When it comes to industrial pumps, the rotary lobe pump is an essential component in many applications. Whether it's for handling viscous fluids, transferring slurries, or dealing with delicate processes, the performance of this type of pump relies heavily on its maintenance and lubrication. In this article, we'll dive into the critical role of lubrication in maintaining the efficiency, longevity, and optimal performance of rotary lobe pumps, specifically focusing on how this affects their operation.

What Is a Rotary Lobe Pump?

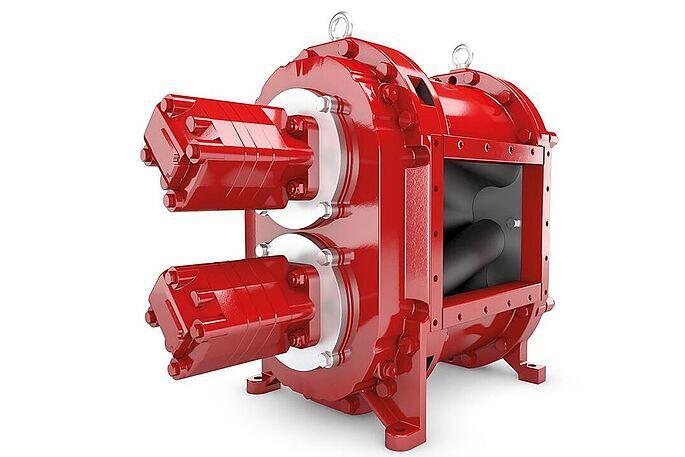

Before we dive deep into the importance of lubrication, let's first understand what a rotary lobe pump is. A rotary Lobe Pump is a type of positive displacement pump used for moving fluids through pipes. It consists of two or more lobes that rotate within the pump chamber, creating suction and discharge. These pumps are highly versatile and can handle a wide range of fluids, from water to thick, viscous substances like oils, slurries, and food products.

The ability to move fluids efficiently while maintaining a consistent flow makes the rotary lobe pump a popular choice in various industries, including food processing, chemical manufacturing, wastewater treatment, and even pharmaceuticals.

How Does Lubrication Affect Rotary Lobe Pump Performance?

Lubrication plays a pivotal role in the operation of a rotary lobe pump. The primary function of lubrication is to reduce friction between the moving parts of the pump, ensuring smooth operation. Here's a closer look at how lubrication directly impacts pump performance:

1. Minimizing Wear and Tear

The rotating lobes inside a rotary lobe pump experience significant friction during operation. Without proper lubrication, this friction can cause the internal components to wear out quickly, leading to reduced efficiency and potential pump failure. Lubrication acts as a protective barrier, reducing direct contact between the metal surfaces, which in turn minimizes the wear and tear on the lobes, shaft, and other moving parts.

2. Preventing Overheating

Friction generates heat, and without proper lubrication, the components of the pump can overheat, which may lead to thermal damage. The lubrication system ensures that the internal parts of the rotary lobe pump are kept cool by reducing friction, allowing the pump to operate at optimal temperatures. Overheating can cause the pump to seize or fail, resulting in costly repairs and downtime.

3. Ensuring Consistent Performance

A well-lubricated rotary lobe pump ensures a smooth and steady flow of the pumped fluid. When lubrication is inadequate, the pump’s performance can fluctuate due to inconsistent movement of the lobes. Proper lubrication helps maintain a steady and predictable flow, which is essential for operations that require precision, such as in the food or pharmaceutical industries.

4. Increasing Pump Lifespan

One of the most important benefits of lubrication is the extension of the pump’s lifespan. By reducing friction and wear, lubrication significantly increases the durability of the rotary lobe pump. Pumps that are regularly lubricated are less likely to experience breakdowns, leading to longer operational life and a lower total cost of ownership.

Types of Lubricants for Rotary Lobe Pumps

Choosing the right lubricant for your rotary lobe pump is critical to its overall performance. Not all lubricants are created equal, and using the wrong type can lead to damage and inefficiency. Here are the most commonly used lubricants in rotary lobe pump systems:

1. Mineral Oil-Based Lubricants

Mineral oils are a popular choice due to their ability to provide sufficient lubrication and cooling. These oils are derived from petroleum and have been used for many years in industrial machinery. They are effective at reducing friction and are often used in rotary lobe pumps that handle moderate to low-viscosity fluids.

2. Synthetic Lubricants

For applications that require higher performance and longer oil life, synthetic lubricants are often preferred. Synthetic oils are engineered to withstand higher temperatures and more extreme conditions. They are ideal for rotary lobe pumps used in high-demand settings, such as in the chemical or pharmaceutical industries.

3. Food-Grade Lubricants

In industries such as food processing, hygiene and safety are paramount. Food-grade lubricants are specifically designed for pumps that come into contact with food products. These lubricants are non-toxic and can safely be used in applications where food safety regulations must be met.

4. Greases

Greases are sometimes used in rotary lobe pumps that require additional protection against contaminants. Grease lubrication is especially useful in pumps that handle semi-solid or highly viscous fluids. Grease stays in place longer than oils, providing consistent protection over time.

Signs That Your Rotary Lobe Pump Needs Lubrication

Knowing when to lubricate your rotary lobe pump is essential for maintaining peak performance. Some signs that indicate your pump may need lubrication include:

1. Increased Operating Temperature

If the pump is running hotter than usual, it’s a sign that friction is building up. This could mean that the lubrication system is failing or insufficient. Regular checks on operating temperatures can prevent damage caused by overheating.

2. Reduced Flow Rate

If you notice a decrease in the flow rate, it could be due to increased friction in the pump. Proper lubrication ensures that the pump continues to operate at the desired capacity without struggling to move the fluid.

3. Unusual Noises

Grinding, squealing, or whining noises are often the result of insufficient lubrication. These sounds indicate that there is excessive friction between the moving parts, which can lead to wear and eventually cause the pump to break down.

4. Increased Vibration

Inadequate lubrication can lead to parts becoming misaligned or worn, which can result in excessive vibration. Regular lubrication helps keep the parts aligned and ensures smooth operation.

The Importance of Regular Maintenance for Rotary Lobe Pumps

Like any other piece of machinery, rotary lobe pumps require regular maintenance to perform at their best. Maintaining proper lubrication is just one aspect of a comprehensive maintenance routine. Regular checks of the lubrication system, seals, and pump parts can help identify potential issues before they cause significant damage. Routine maintenance should include:

- Checking and replacing the lubricant as necessary

- Inspecting seals for leaks

- Ensuring the lubrication system is functioning properly

- Monitoring the pump’s performance regularly

Choosing the Right Lubrication System for Your Rotary Lobe Pump

Selecting the right lubrication system is crucial for ensuring the longevity and optimal performance of your rotary lobe pump. Factors such as the type of fluid being pumped, the temperature conditions, and the pump's operational environment all play a role in determining the best lubrication solution. For example, if you're dealing with highly viscous fluids, a heavier, more viscous lubricant might be necessary.

At Ace Lobe Pumps, we understand the importance of proper lubrication in maintaining high-performing rotary lobe pumps. We offer expert guidance to help you choose the best lubrication solutions for your specific application.

Troubleshooting Lubrication Issues in Rotary Lobe Pumps

Lubrication problems are not uncommon, and identifying them early can save you from costly repairs and downtime. Some common lubrication issues include:

- Contaminated Lubricant: If the lubricant becomes contaminated with dirt, water, or other debris, it can cause significant damage to the pump’s components. Regular filtration and cleaning of the lubrication system are essential to prevent contamination.

- Excessive Lubricant: Over-lubrication can lead to the pump becoming clogged, reducing efficiency and leading to higher energy consumption. It’s important to use the right amount of lubricant as specified by the manufacturer.

- Improper Lubricant Viscosity: Using a lubricant that is too thick or too thin for the application can cause issues. It’s essential to match the lubricant’s viscosity to the requirements of the pump.

Conclusion

In conclusion, lubrication is a vital element in ensuring the longevity, efficiency, and smooth operation of a rotary lobe pump. Proper lubrication reduces friction, minimizes wear, and prevents overheating, all of which contribute to maintaining optimal performance. Regular maintenance and the right choice of lubricants will ensure that your pump continues to perform reliably for years to come.