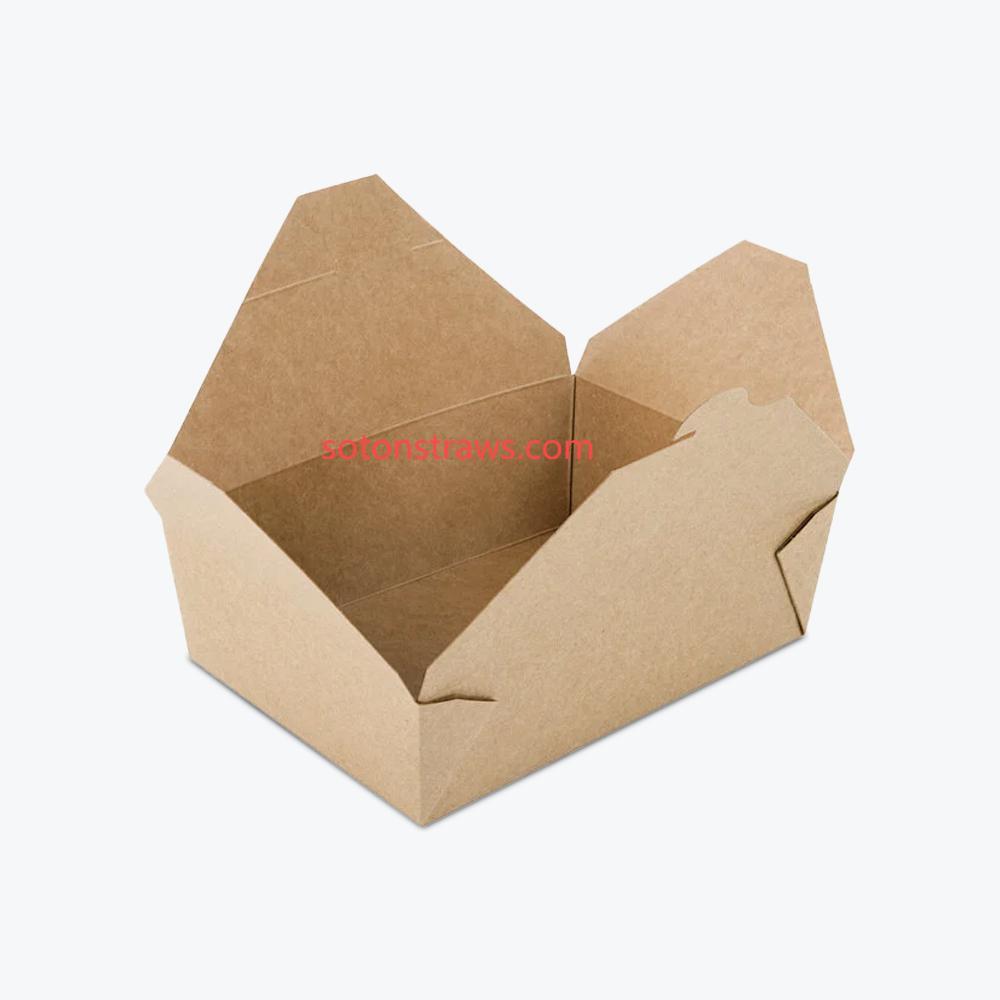

Achieving genuine industrial compostability while fulfilling aggressive price mandates represents a formidable technical challenge for disposable kraft box producers. The scientific reality clashes with commercial expectations, creating friction that threatens both viability and credibility.

True certification requires meticulous material synergy. The kraft paper itself must originate from unbleached, chemical-free pulps. Linings must decompose alongside food waste within commercial composting timeframes without leaving microplastic residues. Many plant-based films meeting these standards struggle with performance fundamentals – resisting hot oils, maintaining adhesion during freezing temperatures, or preventing moisture migration that degrades the paper structure. Manufacturers investing in premium compliant linings then face the paradox of brands demanding thinner applications to reduce costs, rendering the solution ineffective for greasy foods.

Performance testing reveals deeper complications. Certified compostable linings may pass laboratory tests yet fail in real-world facilities where composting conditions vary wildly. A box performing perfectly in one city’s high-heat composting system might persist for months in another region’s lower-temperature operation. This inconsistency creates liability risks for manufacturers when municipalities reject compromised loads contaminated by non-degrading packaging.

The certification maze itself consumes resources. With standards differing across regions – and major brands requiring compliance across all operational territories – manufacturers navigate overlapping and sometimes contradictory requirements. Maintaining multiple certified material formulations for different markets fragments production efficiency and inventory management. Smaller makers risk obsolescence as certification costs become prohibitive.

Soton Advantage:

Soton deciphers the disposable kraft box compostability puzzle through science and scale. Our regionalized material formulations adapt to local composting environments without performance trade-offs. Soton’s unified certification platform covers global standards through a single audit process, reducing complexity by over half. We provide manufacturers with compostability certainty and cost predictability – turning regulatory hurdles into competitive moats. Choose Soton for future-proof sustainable packaging.click https://www.sotonstraws.com/product/biodegradable-straws/st101-paper-straws/ to reading more information.