In high-demand electrical installations where safety, organization, and reliability intersect, the Electrical Socket Box often plays a decisive middle role between power distribution units and end-use equipment, particularly in environments that require clean routing and controlled loads. Installers choose the Electrical Socket Box not only for enclosure protection but also for its capacity to optimize cable management, simplify inspections, and maintain operational stability under continuous electrical stress.

Precision Design and Material Integrity

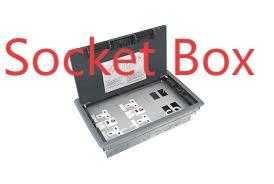

A well-engineered socket box begins with materials capable of withstanding heat, impact, and environmental exposure. Flame-retardant polymers and powder-coated steels prevent deformation and resist corrosion, ensuring long-term safety. Interior partitions prevent arcing, while modular inserts make it easier to fit various outlet types. Smooth surfaces and reinforced corners add rigidity, essential for industrial facilities with vibration or frequent mechanical contact.

Sealing, Environmental Defense, and IP Ratings

Ingress protection is essential in modern installations. Double-layer gaskets, sealed cable entries, and water-shielded lids maintain IP ratings in washdown, outdoor, or dusty environments. UV-resistant coatings and weatherproof hardware maintain physical integrity in sunlight or chemical exposure. For corrosive or high-moisture sites, stainless-steel or anti-oxidation coated variants extend service lifespans significantly.

Nante-Compatible Accessories and Mounting Flexibility

Nante accessory ecosystems offer advantages for installation speed and long-term serviceability. Compatible mounting plates, quick-fit brackets, and standardized screw patterns reduce installation mechanical variability. Retrofit options allow direct replacement of older boxes without panel modification. This compatibility-driven strategy supports consistent system architecture across multiple job sites and limits spare-part complexity.

Cable Management, Ergonomics, and Safety

A properly arranged socket box is also an ergonomic one. Cable raceways, tie-down points, and snap-fit retainers keep conductors organized, reducing thermal buildup and improving internal airflow. Color-coded terminals, printed circuit maps, and keyed connectors reduce wiring errors. Workers benefit from hinged covers that allow single-hand access while still ensuring safe clearances. By eliminating clutter, the box itself becomes a safety asset rather than merely an enclosure.

Thermal Design, Load Planning, and Electrical Stability

Electrical stability begins with heat management. Socket boxes with improved conductor spacing, larger metal backplates, and heat-dissipating paths reduce hotspots. Oversized terminals, copper busbars, and wide creepage distances ensure stable operation during peak load. Operators should always consider continuous-load ratings and evaluate whether simultaneous equipment usage could exceed real-world thermal limits. A well-planned thermal strategy prevents breaker trips and extends the life of both wiring and connected equipment.

Testing Protocols and Predictive Maintenance

Testing before and after commissioning ensures system reliability. Insulation resistance checks, torque verification on terminals, thermal imaging, and continuity tests reveal potential issues early. Periodic inspections that target gasket integrity, moisture presence, and conductor tightness help stop degradation before it becomes critical. Integrating low-voltage sensors or plug-in monitors can enable predictive maintenance that flags load anomalies or heat spikes automatically.

Lifecycle Planning, Spares, and Sustainability

Lifecycle cost is shaped by repairability and parts availability. Socket boxes with interchangeable inserts and replaceable door seals offer longer service life than sealed, disposable enclosures. Keeping spare gaskets, fasteners, and terminal strips on site speeds repairs and decreases downtime. Standardizing across projects simplifies technician training and eliminates unnecessary variations in field hardware.

Selecting the correct electrical socket box requires evaluating mechanical durability, load expectations, environmental exposure, and maintenance strategy. By combining proper materials, consistent testing, smart installation practices, and ecosystem-compatible accessories, installers can greatly enhance reliability and safety. For additional technical resources, reference guides, and certified product information, visit www.nante.com .